MIL-DTL-16377J(SH)

4.4.1 Comparison inspection. One sample from the first production run on each fixture, light, or part shall be

subjected to the same inspection specified in the applicable specification sheets for first article inspection when

specified (see 6.2 and 6.9). Procedures for first article inspection specified in 4.3 shall also apply for comparison

inspection.

4.4.2 Inspection of product for delivery. Inspection of product for delivery shall consist of the following:

a.

Examination of 4.5.

b.

Conformance tests of 4.6.

c.

Examination for preparation of delivery of 4.7.

4.4.2.1 Sampling plan for inspection of product for delivery. Sampling plan for inspection of product for

4.4.2.1.1 Lot. For the purpose of sampling, a lot shall be the identical number of items on the contract or order.

4.4.2.1.2 Sampling for examination and conformance tests. As a minimum, the contractor shall randomly

select a sample quantity of fixtures from each lot in accordance with table IV and examine them as specified in 4.5

and 4.6. Detection of any nonconforming characteristic in any sample shall result in the rejection of the entire lot.

The contractor has the option of screening 100 percent of the lot for the defective characteristic(s) or providing a

new lot which shall be inspected in accordance with the sampling plan contained herein.

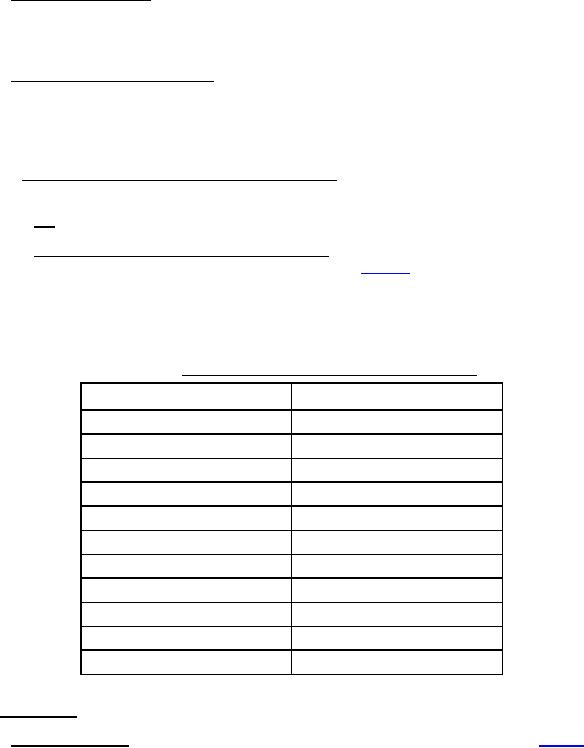

TABLE IV. Sampling for examination and conformance tests.

Lot Size

Sample Size

2 to 4

1

5 to 50

5

51 to 90

7

91 to 150

11

151 to 280

13

281 to 500

16

501 to 1,200

19

1,201 to 3,200

23

3,201 to 10,000

29

10,001 to 35,000

35

35,001 and over

40

4.5.1 Visual examination. Fixtures, lights, or parts shall be examined for the defects listed in table V, as

applicable.

25

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business