MIL-DTL-16377J(SH)

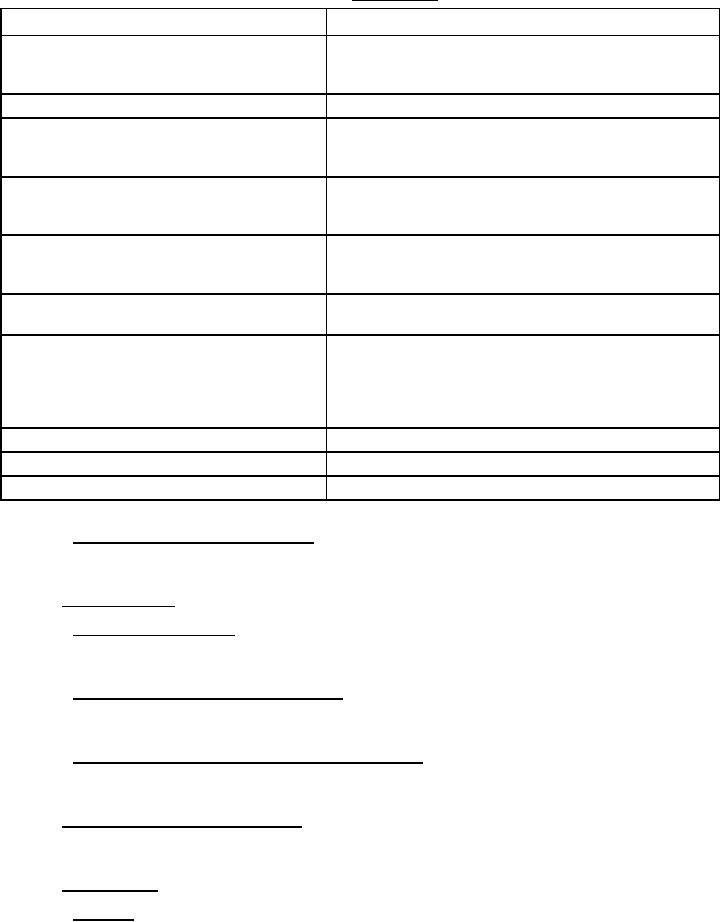

TABLE V. Visual defects.

Examine

Defect

Finish

Finish not as specified: blistered, peeled, chipped, area of no

film or insufficient diffusion.

Color not as specified.

Materials

Materials not as specified.

Construction and workmanship, general

Part missing, fractured, split, punctured, dented, or

(applicable to all parts and assemblies)

deteriorated. Not in proper alignment. Sharp burr or edge,

silver or splinter.

Welding and brazing (where applicable)

Missing, incomplete, burn holes, cracked, fractured, or

otherwise not fused, slag inclusion, slight undercut, not

smooth and uniform, scale or flux deposits not removed.

Soldering (when applicable)

Missing, not adherent or incomplete. Not clean (flux or flux

residue not removed); not smooth (surface not finished

neatly), or pinholes in solder.

Bolts, nuts, screws, studs, pads, rivets, and other

Missing, broken, stripped, fractured, loose, bent, not peened or

types of fasteners

insufficiently peened.

Electrical assembly

Connections at screw terminals and splice connection not as

specified. Wiring not properly joined, loose at terminal, or

not enclosed in specified conduit where required.

Adequate slack not provided for wiring to relieve similar or

excessive insulation stripped from wiring.

Gaskets (where applicable)

Not coated where required, missing, not as specified.

Marking for identification

Missing, incomplete, not legible.

Tag or sheet (where applicable)

Missing, incomplete, not legible.

4.5.2 Examination for weight and dimensions. Fixtures, lights, or parts shall be examined to determine

compliance with weight and dimensional requirements. Weights or dimensions not within specified tolerances shall

be classified a defect.

4.6 Conformance tests. Fixtures, lights, or parts shall be subjected to the tests specified in 4.6.1 through 4.6.3.

4.6.1 Complete fixtures or lights. Sample fixtures or lights shall be subjected to the operation, the dielectric

withstanding voltage, and the insulation resistance tests of 4.8.1, 4.8.2, and 4.8.3. Additionally, Type III luminaires

shall be subjected to the chromaticity test of 4.8.25.

4.6.2 Plastic windows for type I fixtures and lights. Sample plastic windows for Type I fixtures and lights shall

be subjected to the optical uniformity and stress relief tests of 4.8.4 and 4.8.5. These tests shall be performed when

the windows are furnished as an integral part of a fixture or light or as a repair part.

4.6.3 Lenses, globes, and roundels for type II fixtures and lights. Lenses, globes, and roundels for Type II

fixtures and lights shall be subjected to the optical uniformity test of 4.8.4. This test shall be performed when the

lenses, globes, and roundels are furnished as an integral part of a fixture or light or as repair parts.

4.7 Examination for preparation of delivery. Sample packages and packs and the inspection of the

preservation, packing, and marking for shipment and storage shall be in accordance with the requirements of

section 5.

4.8 Test procedures.

4.8.1 Operation. The fixtures, lights, and parts shall be electrically and mechanically operated to determine

conformance to the requirements of this specification.

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business