MIL-DTL-16377J(SH)

A

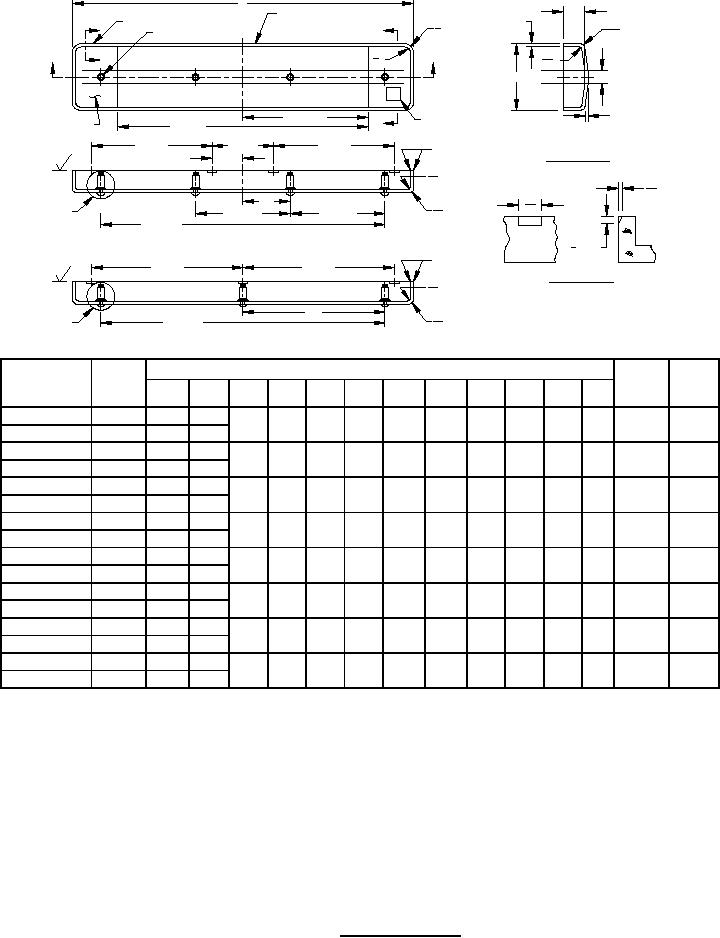

C±1/32 (INSIDE)

THE SURFACE SHALL BE

NOTE 4

0.250±0.035

1

C

FLAT ALL AROUND

C

5

L

2R

16R

B

NOTE 5

WITHIN 1/16

1

1

A

A

4R

16R

C

3/4 FLAT

A

D±1/32

M/2±1/32

NOTE 5

B

NOTE 7

M±1/16

AT PROJECTED

SHARP CORNER

J±1/32

K±1/32

K±1/32

NOTE 6

SECTION B-B

J/2

150

1

16R

1 ±1/32

16

7

E/2

5

32

16R

NOTE 3

E±0.015

F±0.015

G±0.031

SECTION A-A - SHOWING FOUR NOTCHES AND FOUR MOUNTING HOLES

1+1/16

8 -1/32

NOTE 6

L±1/32

L±1/32

150

SECTION C-C

1

16R

DETAILS FOR WINDOW NOTCH

(THESE DIMENSIONS MAY VARY ON

H/2

PRISMATIC WINDOWS DUE TO

5

16R

H±0.031

NOTE 3

IRREGULAR INTERSECTIONS OF

SECTION A-A - SHOWING THREE NOTCHES AND THREE MOUNTING HOLES

NOTCHES WITH PRISM)

Dimension

No. of

No. of

Military Part

Secrg. notches

Material

No.

A

B

C

D

E

F

G

H

J

K

L

M

Scr. assy ea. side

M16377/5-001

Note 1

22.875

4.593

119/64

541/64

721/32

19.125

17

3

4

M16377/5-002

Note 2

22.797

4.562

M16377/7-001

Note 1

17.234

4.593

721/32

13.312

½

11

3

3

M16377/7-002

Note 2

17.187

4.562

M16377/8-001

Note 1

28.875

4.593

119/64

831/32

25.125

8¾

23

3

4

M16377/8-003

Note 2

28.797

4.562

M16377/9-001

Note 1

16.015

7.265

79/64

/32

/16

31

7

11.782

11

3

3

M16377/9-003

Note 2

15.968

7.203

M16377/11-001

Note 1

28.656

7.265

/16

1

9

8.333 8.396 25.125

8¾

8¾

23

4

4

M16377/11-003

Note 2

28.563

7.203

M16377/12-001

Note 1

28.937

9.234

131/64

91/32

/32

25

8.333 8.396 25.125

8¾

23

4

4

M16377/12-004

Note 2

28.844

9.141

M16377/65-001

Note 1

22.656

7.265

/16

1

9

6.375 6.375 19.125

6¾

6¾

17

4

4

M16377/65-002

Note 2

22.563

7.203

M16377/66-001

Note 1

22.937

9.234

131/64

/32

25

6.375 6.375 19.125

6¾

6¾

17

4

4

M16377/66-002

Note 2

22.844

9.141

NOTES:

1.

Material shall be ¼ inch thick, white translucent acrylic plastic, Type WTLS-4, Grade G of MIL-DTL-24191.

2.

Material shall be ¼ inch thick, clear prismatic acrylic plastic, Type CLEAR-2 of MIL-DTL-24191. The prisms shall be on the outside

surface of the windows.

3.

Short window securing screw assemblies in the number indicated on the table shall be installed as specified in 3.7.6.1.3.

4.

When required, notches in the number indicated on the table shall be filed as shown as specified in 3.7.6.1.4.

5.

Drill 0.191 diameter hole and counterbore opposite side 0.323 diameter, 0.050 deep. Break sharp edges on the inside surface on all holes.

Break sharp edges 1/64 of an inch around entire window.

6.

7.

The inside surface of both ends (bottom, sides, and end) of windows with clear prismatic material shall be finished white as specified in

8.

When required, one Type VI label shall be applied on the outside surface of the white translucent windows and on the inside surface of the

clear and white prismatic windows as specified in 3.7.6.1.3.

FIGURE 27. Window assemblies.

53

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business