MIL-DTL-16377J(SH)

5

5

16 OD

16 OD

1

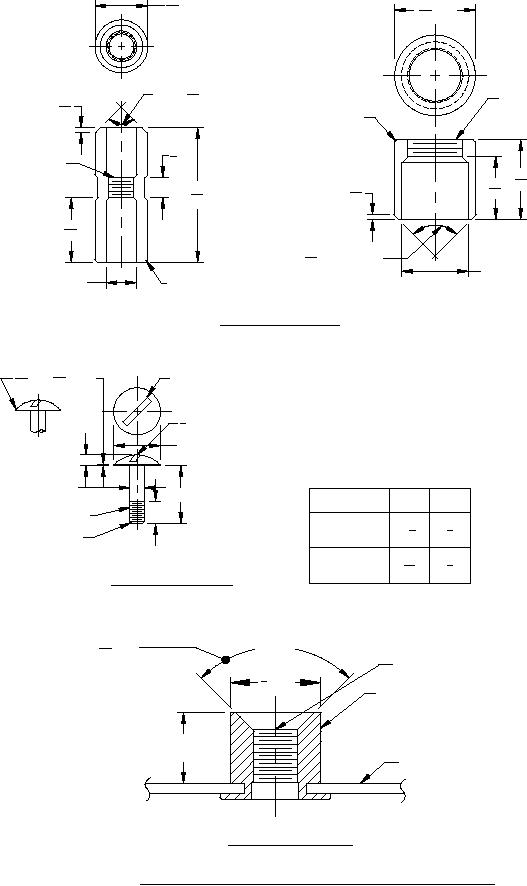

90° X 32 CHAMFER

TAP 10-24UNC-2B -

1

32

MIN. ID 0.172 AFTER

BREAK SHARP EDGE

THREADING

1

8

TAP 10-24UNC-2B -

7

MIN. ID 0.172 AFTER

11

32

1

41

THREADING

64

32

64

11

32

1

90° X 32 CHAMFER

+0.026

0.196-0.005 ID

+0.026

0.196 -0.005 ID

BREAK SHARP EDGE

(SHORT)

(LONG)

(A) - CAPTIVE BUSHINGS

0.070

0.080

1

1

32 FLAT

64R

DEEP SLOT

WIDE X

0.080

0.090

MATERIAL:

0.139

3

8R

CAPTIVE BUSHINGS SHALL BE BRASS, NICKEL

0.129

PLATED, OR ALUMINUM.

0.500

ALTERNATE HEAD

DIA.

0.470

SCREWS SHALL BE BRASS, NICKEL PLATED, OR

FOR MOUNTING

CORROSION RESISTANT STEEL.

SCREW

0.1629

DIA.

"A"

0.1596

USED WITH

"A"

"B"

"B"

10-24UNC-2A THREAD

FIXTURE 1

3

1

14

8

(LONG)

SLIGHT LEAD

FIRST THREAD

FIXTURE 2

3

13

16

8

(SHORT)

(B) - SECURING SCREWS

21

90°

90° C'SINK X 64 DIA.

TAP 10-24UNC-2B

3

8 DIA.

MOUNTING BUSHING SHALL BE EITHER

NOTE:

CORROSION RESISTANT STEEL, STEEL

MOUNTING BUSHINGS SHALL

ZINC PLATED, OR ALUMINUM WITH

BE PROVIDED IN FIXTURES

CRES THREADED INSERT.

TO

FOR WINDOW MOUNTING

SUIT

USING THE CAPTIVE BUSHINGS

FIXTURE STRUCTURE

AND SECURING SCREWS

SHOWN.

(C) - MOUNTING BUSHING

FIGURE 3. Captive bushings, securing screws, and mounting bushings.

36

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business